Leading RFID Cards Manufacturer In China

Discover how one of China’s top 5 manufacturers leads RFID cards manufacturing in the world, offering innovative and customizable solutions for global brands.

When a cruise ship docks after a 7-day voyage, 800 bedsheets vanish. At mega sporting events, 15% of staff uniforms disappear before halftime. For industries battling “textile black holes,” UHF RFID Laundry Textile Labels are digital guardians – these rugged microchips woven into fabrics solve mysteries even Sherlock would envy. Let’s decode their game-changing applications across global supply chains.

(Ultra High Frequency) UHF RFID laundry textile tags operate at 860-960 MHz, enabling long-range scanning up to 15 feet and fast batch detection, perfectly solving the problem of low efficiency of manual scanning. Each tag contains a microchip and antenna, encapsulated in materials such as silicone or thermoplastic polyurethane (a variety of materials are available), and can withstand industrial washing machines (up to 95°C/203°F) and more than 200 wash cycles. These excellent properties make them particularly suitable for use on clothes and textiles.

Hotels face a silent crisis: 15-20% of linens vanish annually through theft or misplacement. UHF RFID Laundry Textile Labels solve this by:

Case Study: A Beverly Hills hotel slashed annual linen replacement costs by $120,000 and reduced inventory audits from 8 hours to 20 minutes.

Hospitals lose up to 30% of linens monthly, risking cross-contamination. UHF Textile Labels enable:

Casinos manage thousands of staff uniforms daily. UHF RFID systems:

High-traffic gyms lose 50+ towels daily. RFID-labeled textiles:

Large laundries use UHF RFID to:

| Metric | UHF RFID Laundry Textile Labels | Barcodes/Manual Tracking |

|---|---|---|

| Scan Speed | 500+ items/sec | 1-2 items/sec |

| Read Range | Up to 15 feet | Line-of-sight required |

| Durability | 200+ industrial washes | Fades in 30-50 cycles |

| Theft Deterrence | Real-time alerts & geofencing | “Lost & Found” black holes |

| ROI Timeline | 8-14 months | Forever cost sink |

UHF RFID Laundry Textile Labels are engineered for survival:

Fun Fact: Tags often outlast the linens they’re attached to—one manufacturer reported 7-year lifespans!

While generic RFID tags fail mid-cycle, our stress-tested UHF RFID Laundry Textile Labels thrive:

UHF RFID laundry labels aren’t just tags—they’re your gateway to:

Ready to Transform Your Textile Workflow?

In a world where 260 million tons of textiles are wasted yearly, UHF RFID Laundry Textile Labels ensure every thread counts.

Newest trends and common knowledge in RFID laundry tags.

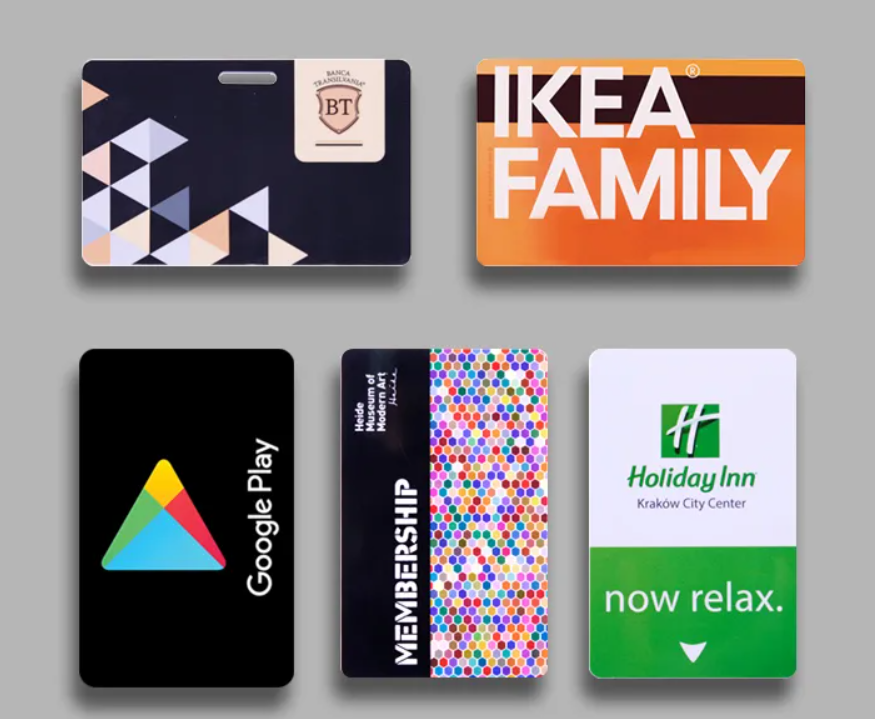

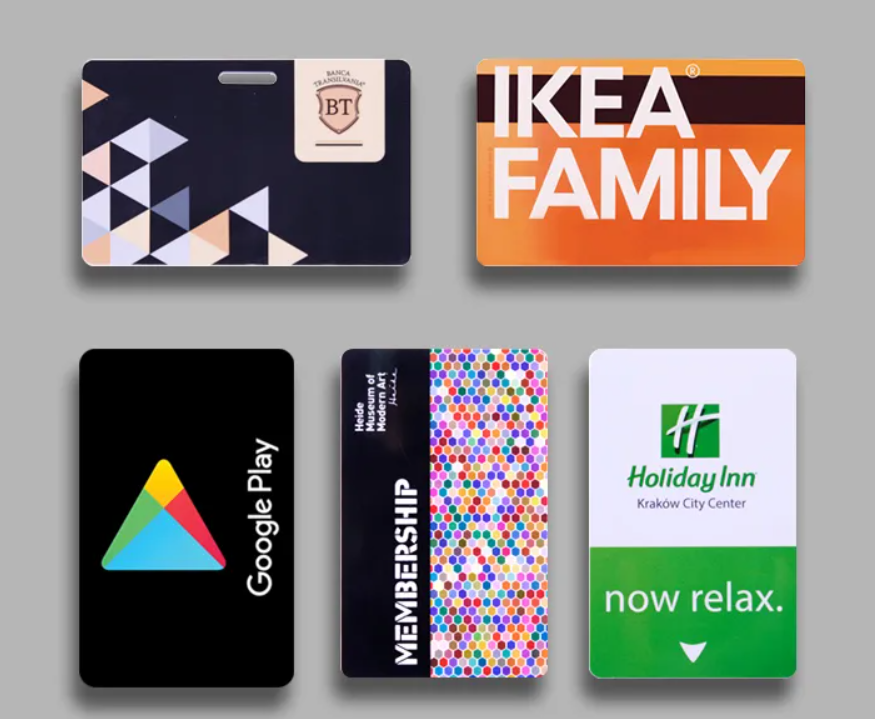

Discover how one of China’s top 5 manufacturers leads RFID cards manufacturing in the world, offering innovative and customizable solutions for global brands.

Learn how to program and use MIFARE S50 NFC Tags for secure, contactless applications. Perfect for access control, automation, and more!

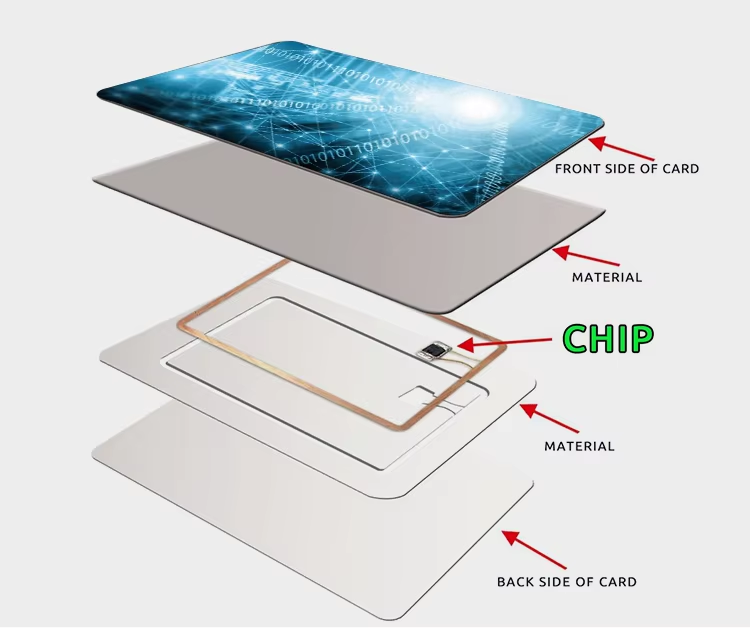

Discover RFID Smart Cards: secure, durable, contactless IC cards for payment, access control & ID. Upgrade to smarter, faster, encrypted card solutions today!

As one of the top RFID Tag manufacturers in China, we specialize in high-quality RFID Tag and other RFID products designed to meet the diverse needs of various industries.

@ 2024 RFID Laundry Tag. All right reserved.

Didn’t find what you want? Ask our manager for help!