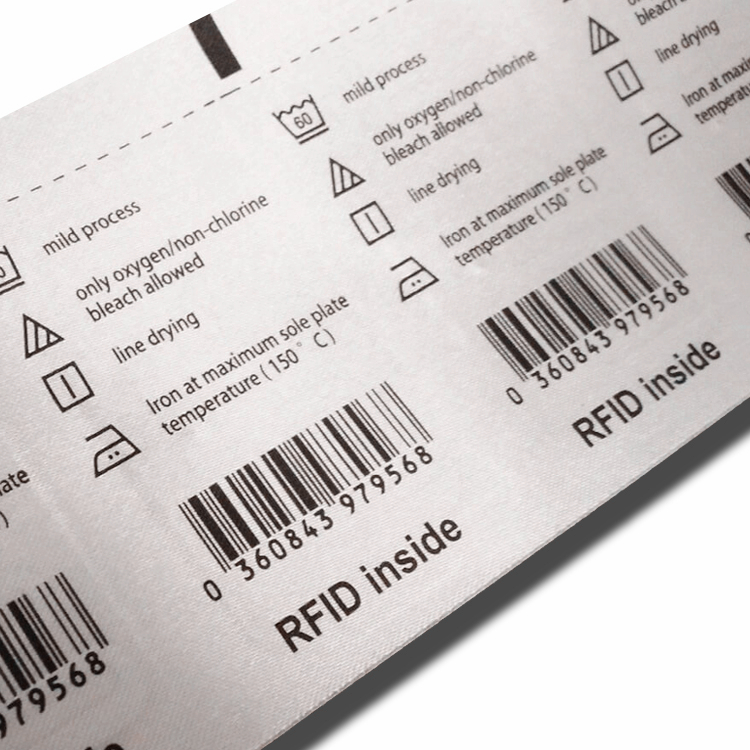

UHF Passive Garment Production RFID Label

UHF Passive Garment Production RFID Label streamline garment inventory management, offering fast, accurate tracking and durability for efficient operations.

Description

UHF Passive Garment Production RFID Label

The UHF Passive Garment Production RFID Label is a game-changer in the world of inventory management, designed specifically for the garment industry. By integrating advanced RFID technology, these labels streamline the tracking of items, ensuring efficient operations while reducing labor costs and human error. With a robust construction and adaptability to various garment types, these RFID labels are not just functional but also enhance the overall management of apparel inventory.

In this comprehensive guide, we will delve into the features, benefits, specifications, and real-world applications of these remarkable RFID labels, demonstrating why they are essential for modern garment production.

Understanding UHF RFID Technology

UHF RFID (Ultra High Frequency Radio Frequency Identification) is a technology that allows for the automatic identification of tags attached to objects. The Custom UHF Passive Garment Production RFID Label operates under the EPC C1G2 (ISO18000-6C) standard, capable of communicating with UHF RFID readers operating in the 860-960 MHz frequency range. This capability allows for fast, accurate inventory checks, making it ideal for high-volume garment production settings.

How UHF RFID Works

UHF RFID systems work by using electromagnetic waves to transmit data between a tag and a reader. The Custom UHF Passive Garment Production RFID Label can be read without a direct line of sight, allowing multiple labels to be scanned simultaneously. This feature is particularly advantageous in warehouse environments where items are stored in high-density racks, as it drastically reduces scanning time and improves efficiency.

Key Benefits of RFID Labels in Garment Production

- Increased Efficiency: Implementing RFID labels allows for rapid inventory checks and management. This means less time spent locating products and more time dedicated to production processes.

- Enhanced Accuracy: With RFID, the potential for human error in inventory counts is significantly reduced. The automated processes ensure that garment counts are precise, which is crucial for tracking sales and stocking.

- Cost Savings: By minimizing error and streamlining operations, businesses can save on labor costs. The initial investment in RFID technology can lead to substantial long-term savings through improved efficiency.

Features of Custom UHF RFID Labels

The UHF Passive Garment Production RFID Label are engineered with various features:

- Multiple and Simultaneous Reading: This technology allows for the reading of numerous labels in a single pass, making inventory processes faster and more efficient.

- Long Read Range: Capable of being read from 1-5 meters, depending on the reader and antenna, these labels provide flexibility in how they can be used in different environments.

- Customizable Options: These RFID labels support OEM and ODM customization, allowing businesses to select the appropriate size and material for their specific applications.

- Durability and Water Resistance: Designed to withstand various environmental factors, these UHF waterproof RFID labels endure washing and high-stress conditions, ensuring longevity.

Technical Specifications

Specifications Table

| Specification | Details |

|---|---|

| Name | Custom UHF Passive Garment RFID Label |

| RFID Chip | Alien H3 / Impinj M5 |

| Protocol | ISO/IEC 18000-6C, EPCglobal Class 1 Gen2 |

| Operating Frequency | UHF 860-960 MHz |

| Operating Mode | Passive (Battery-free) |

| Memory | 64-bit TID, 96-bit EPC, 512-bit User Memory, 32-bit Access, 32-bit Kill |

| IC Life | 100,000 Programming cycles, 10 years data retention |

| Average Reading Distance | Reader and Environment Dependent |

Environmental Benefits of Using RFID Labels

Using UHF Passive Garment Production RFID Labels not only improves efficiency but also contributes positively to environmental practices:

- Waste Reduction: By optimizing inventory processes, businesses can reduce overproduction and waste.

- Sustainable Materials: Many RFID labels can be made from environmentally friendly materials, which helps businesses comply with regulations and meet consumer demands for sustainable practices.