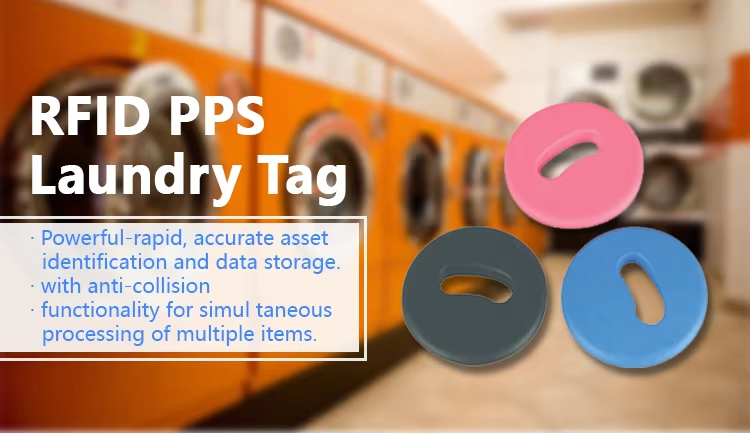

Who Should Invest in PPS RFID Laundry Tags?

Discover how investing in PPS RFID laundry tags can enhance efficiency, reduce losses, and streamline operations for hotels, hospitals, and dry cleaners.

Food safety issues have shocked the public more than once. From “frozen meat smuggling” to “sick and dead animals re-entering the market,” the fundamental problem exposed by this series of events is the lack of a complete system that can be checked, controlled, and traced. Only by truly realizing the whole process tracking from source to table can we build a food safety ecosystem that everyone can rest assured about.

The key to achieving food traceability lies in the “consistency” of information. For example, a pig should establish a complete electronic identity file from the day it is born, recording its birth time, farmer information, feed ratio, disease records, etc. It should also be clear which pasture and which cow the raw materials of milk come from. If all this information relies on manual records, it is inevitable that there will be risks such as omissions, errors, and even falsification, low efficiency, and weak traceability.

At this time, the power of science and technology is fully reflected. The introduction of RFID (Radio Frequency Identification) technology, especially RFID Glass Tube Syringe Tag, is completely changing the landscape of animal identification and food traceability.

The RFID Glass Tube Syringe Tag for Animal Identification, independently developed by our factory, is an injection-type RFID tag designed specifically for animals. It uses a low frequency of 134.2KHz, complies with the international ISO11784/11785 FDX-B standard, and is universally used worldwide.

The system achieves information collection, tracking, and data upload by implanting an independent electronic identity tag for each animal, building a scientific, efficient, and queryable animal traceability system. The main application scenarios include:

Integration of Syringe and RFID Tag: The syringe is made of medical-grade polypropylene, easy to operate and each syringe is individually packaged. It is sterilized with EO (ethylene oxide) and is safe and hygienic.

High-Performance Chip Packaging: The core tag is packaged with bioglass, which is small in size (Φ2.12mm × 12mm) and weighs only about 0.1g. The surface is coated with a biological anti-slip coating, which is non-repellent and non-free, and is stable and reliable after implantation.

Unique ID Identification Number: Each tag contains a unique chip ID number, supports data encryption and integrity verification, and the information cannot be tampered with, ensuring the security of animal identity information.

Reading Distance Optimization: The tag can support reading up to about 20cm (depending on the reader and environment), which is convenient for daily inspections and batch identification.

| Article | Parameters |

|---|---|

| Matériau de l'étiquette | Bioglass, anti-slip coating |

| Syringe Material | Polypropylene |

| Label Size | Φ2.12mm × 12mm |

| Syringe Size | 120mm × 46mm |

| Fréquence de fonctionnement | 134,2 kHz |

| Type de puce | EM4305 |

| Disinfection Method | EO (ethylene oxide) gas disinfection |

| Using Temperature | -10℃ ~ +45℃ (no icing) |

| Température de stockage | -20℃ ~ +50℃ (no icing) |

| Service Life | 5 years |

| Packing Method | 20 pieces/pack |

As China’s Top 5 RFID manufacturer, based on the dual technology integration of RFID + one object one code, we have provided complete digital traceability solutions for multiple agricultural, retail, and animal husbandry companies. In the production process, binding RFID tags with unique QR codes can realize batch reading of whole boxes of goods in seconds, which not only improves the efficiency of the B-end supply chain but also enhances the trust of C-end consumers.

In order to meet customers’ stringent requirements for anti-tampering, RFID tags can also be made into fragile tags through special materials and processes. Once torn, they will become invalid, effectively preventing secondary use and information falsification.

From food source control to animal behavior tracking, RFID Glass Tube Syringe Tag has become an indispensable tool for modern food safety traceability. It not only improves the efficiency and accuracy of information recording but also helps the entire industry build a transparent, safe, and sustainable supply chain system.

In the future, let us use technology to protect “safety on the tip of the tongue.”

If you need to learn more about RFID Glass Tube Syringe Tag or get a sample trial, please feel free to contact us.

Dernières tendances et connaissances communes en matière d’étiquettes de blanchisserie RFID.

Discover how investing in PPS RFID laundry tags can enhance efficiency, reduce losses, and streamline operations for hotels, hospitals, and dry cleaners.

NTAG213 NFC cards enable secure, contactless data transfers for payments, ticketing, and access control, enhancing convenience and efficiency.

Discover essential tips for choosing a reliable NFC card manufacturer, focusing on production capacity, quality control, innovation, and strong support.

Vous n'avez pas trouvé ce que vous recherchiez ? Demandez de l'aide à notre responsable !