Where to Buy High-Quality NFC Key Tags?

Discover high-quality NFC key tags for secure access control. Learn about their benefits, applications, and why you should choose our top-rated factory!

Antennas play a vital role in wireless communications. RFID (Radio Frequency Identification) technology uses electromagnetic waves to transmit data, and antennas are responsible for generating and receiving radio waves. When an electronic tag enters the working area of the reader, the antenna in the tag generates enough induced current to activate the energy required.

In the RFID system, the performance of the antenna has a direct impact on the overall effect. According to the material, structure and manufacturing process of the antenna, RFID tag antennas can be mainly divided into three types: etched antennas, printed antennas and wound antennas. These three processes are currently the most widely used manufacturing methods.

The etching method, also known as the imprint erosion method, first covers the substrate with a 20μm thick layer of copper or aluminum. Next, a corrosion-resistant agent is applied to the surface of the copper or aluminum through screen printing technology to protect the copper or aluminum from corrosion, while allowing other parts to be dissolved by the corrosive agent. Although this method is technically mature, in actual production, the chemical corrosion process takes a long time and produces a lot of wastewater, which will cause certain pollution to the environment. The industry is also actively looking for more environmentally friendly alternatives.

Printed antenna is a relatively new production method. It uses special conductive ink or silver paste to directly print the antenna circuit on the substrate. Common printing techniques include gravure printing and screen printing. Although screen printing can save costs to a certain extent, the silver content in the conductive silver paste used is as high as 70%, and the thickness of the antenna obtained is between 15 and 20μm. It belongs to the thick film printing method, and the cost is relatively high.

The production process of the wound antenna is mainly completed by an automatic winding machine. The process uses insulating paint to directly coat the base media film and uses copper wire with low melting point paint as the substrate of the RFID tag antenna. Then, the wire and the substrate are mechanically fixed with an adhesive, and finally, different numbers of turns are wound as needed to ensure the performance of the antenna.

In summary, etching antenna, printing antenna, and winding antenna are important foundations of RFID tags. These processes have their own characteristics and adapt to different application requirements. In the future, with the continuous development of technology, the manufacturing process of RFID antennas will be more diversified and environmentally friendly. I hope this blog can help you better understand the manufacturing process of RFID tag antennas!

Newest trends and common knowledge in RFID laundry tags.

Discover high-quality NFC key tags for secure access control. Learn about their benefits, applications, and why you should choose our top-rated factory!

Dual Chip RFID Card combines contact & contactless tech in one card, ideal for secure payments, access control & multi-use smart card systems.

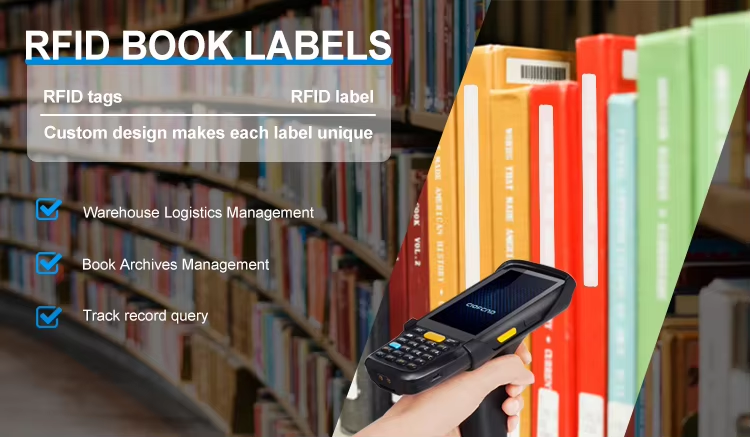

RFID Library Stickers enhance library efficiency, simplify management, and improve user experience with features like self-service borrowing and automatic inventory.

Didn’t find what you want? Ask our manager for help!